|

Case Studies

|

|

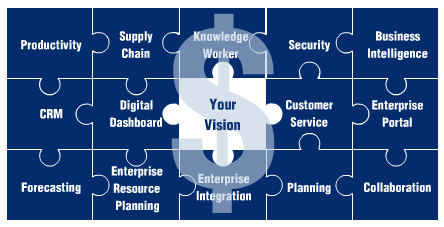

Let Us Put All The Pieces Together For You...

American President Lines (www.apl.com)

American President Lines (APL) moves containerized freight within and between North America and Asia. The company traces its origin back to 1848, and now employs more than 5,000 people worldwide. APL's modes of transportation are rail, truck, and ship. Many times, large organizations such as APL face work process challenges. One such work process problem that APL faced was in their invoice creation for customers. APL had approximately 55% of its retail accounts receivables in a "past due" state. Much of this situation was a consequence of customers being sent invoices that contained incorrect information or inadequate documentation. These customers disputed their bills and refused to pay them until they were corrected. As a result, APL's accounts receivable personnel did a lot of rework to correct the invoices. Rework is one of the most costly activities a company can incur, because it takes longer and costs more to fix a problem than to do it correctly up front. Also, the poor quality of these invoices had a negative impact on customer perceptions and was jeopardizing goodwill, as well as frustrating employees. Therefore, APL had to devise a way to push quality to the source and "Do it right the first time."

Upon investigation, we determined that the computerized information the invoicing department received to create invoices was incorrect and/or incomplete. This information was being put in the system by customer service representatives (CSRs) in field locations, who were unaware of the needs of the invoicing department. So, the departments began communication with each other to get correct and complete information when orders were created. The invoicers compiled weekly manual checklists on each defect type. CSRs were given weekly updates. As the data collection effort matured, all parties agreed on error categories and data collection was automated. In addition, a weekly percentage of error-free orders was calculated and used to track the improvement effort. Finally, it became the task of management to use this data to promote an environment of "quality at the source". To use data positively means the information is used as a teaching tool rather than in a negative and disciplinary manner. For example, weekly results were tracked on a graph. The correct invoice percentage became one of the on-going measures that the CSRs used to gauge the quality of their work. An interesting effect was that the percentage fluctuated (due to the many causes of the defects) while trending upward. Therefore, a regression line was incorporated into the graph to indicate that continuous improvement was being achieved by the CSRs.

Due, in part, to the correct invoicing effort, APL's domestic division reduced its percentage of past due receivables from 55 percent to 8 percent in one year. Additional benefits included:

- Professional communication of defect data as opposed to finger-pointing

- Improved data integrity

- Reduction in uncertainty

- Avoidance of costly rework

- Improved customer satisfaction due to accurate invoices

- Timely feedback: weekly data analysis and communication to individual CSRs

- Positive use: focus on what's right and improving more, not what's wrong and reducing errors

- Teamwork, communication, and empowerment

This example illustrates that high-quality improvements can be made when they are based on the facts that data provides.

If you're looking for small business solutions that work with you, complete this form and someone will contact you.

|

|

|

|